Every decorative floor needs a transparent finish that accentuates the expressive character of the floor. But did you know that you also give valuable extra properties to self-levelling floors and trowel floors with transparent coatings?

In this article you can read more about the quality properties of our transparent coatings and their most important areas of application. We also explain the processing and application process.

Packed with quality features

Our transparent coatings not only accentuate the underlying floor surface, but also offer optimum protection, as verified by the following quality properties:

- UV protection. The coatings protect the underlying system against UV light, slowing the ageing process and yellowing of the floor. For a floor that is colorfast use HIM SL PU-UV (an aliphatic polyurethane) as an underlay.

- Chemical resistance. The coatings can withstand mineral oils and fats, cleaning agents, diluted mineral acids, alkalis and a number of hydrocarbons. (You can request a complete overview from HIM.)

- Solvent free. No odor or taste transfer takes place during the application. The coatings are people and environment friendly.

Applications of transparent epoxy coatings

Our transparent coatings have two important applications:

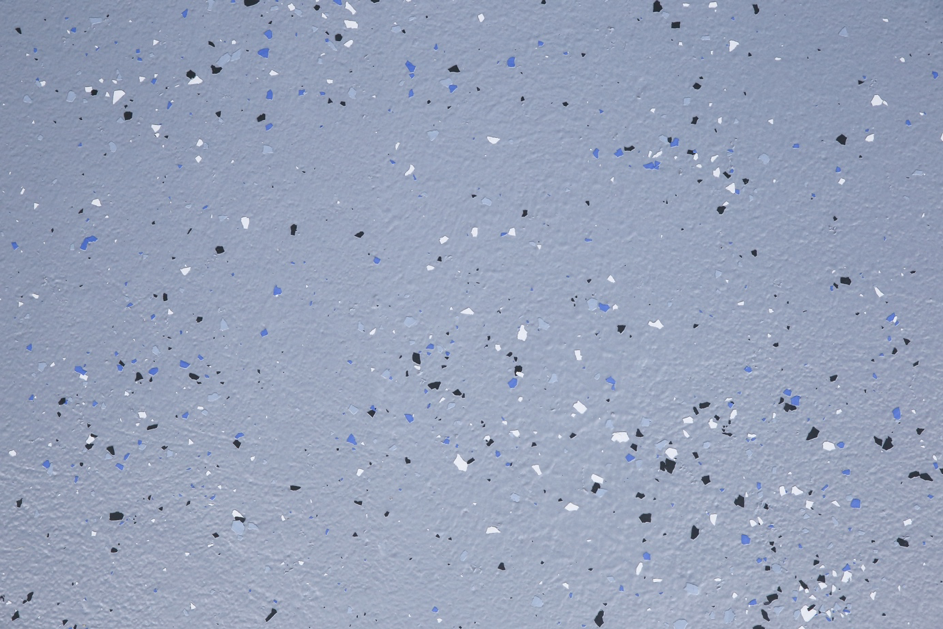

- As a finish on a decorative floor system. Self-leveling floors and trowel floors are available in many different colors and decorative designs. By sprinkling the floor with flakes or producing a concrete look, you create a unique, mixed appearance. To maintain and accentuate the decorative effect of these floor designs you apply a transparent coating.

- As a coating on a concrete or cement floor. If you only want to make a concrete or cement floor dust-resistant, you do not have to install a complete flooring system, such as an epoxy floor or polyurethane floor. In that case, only the coating is sufficient. This way you reinforce the substrate and you retain the industrial look of the room.

Transparent coating easy to apply

HIM has two solvent-free, transparent coatings: HIM FC150 and HIM FC240. HIM FC150 is a transparent mat coating, based on epoxy and HIM FC240 is a polyurethane coating, available in a mat and satin version. Both coatings are easy to apply.

Use

HIM FC150 and HIM FC240 are often used as a single or double finish for epoxy or polyurethane flooring systems. The application process is as follows:

HIM FC150

- Pre-treatment of the substrate. When the surface is clean, dry and no older than 7 days, it does not require any additional pre-treatment.

- Temperature during application. Apply the coating only at a temperature between 10°C and 35°C. The substrate temperature must be higher than the dew point temperature plus 3°C.

- Application. Use a brush or roller for applying. Make sure that the coating covers the entire surface and prevent puddles, which may disturb proper curing.

- Drying and curing process. The coating is dust-dry after 60 minutes, foot traffic is possible after 24 hours and the coating is fully cured after 7 days. Ensure adequate ventilation during drying. If you want to apply a second layer, the first layer must be cured for at least 24 hours.

HIM FC240

- Pre-treatment of the substrate. The surface must be clean, dry and grease free. If the underlying system is not older than 2 days, pre-treatment is not necessary.

- Temperature during application. Apply the coating only at a temperature between 10°C and 35°C. The substrate temperature must be higher than the dew point temperature plus 3°C.

- Application. Use a brush, roller or spraying equipment and apply an even layer thickness. A crosswise application gives the best result.

- Drying and curing process. The coating is dust-dry after 60 minutes, foot traffic is possible after 24 hours and the coating is fully cured after 7 days. A second layer can be applied after approximately 16 hours.

Want to know more about our transparent coatings?

Do you want to know more about our quality floor coatings? Our specialists are happy to help you on your way! For more information, call +31 (0)251-276300 or contact page.

Contact us

Publicatiedatum: 2019-04-04

Categorie: News