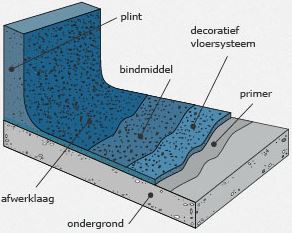

Thickness - 3-10 mm

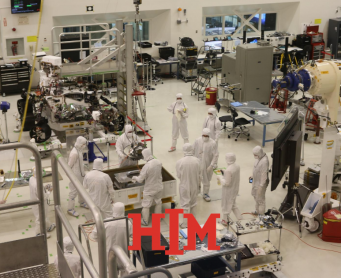

HIM quartz floors are made of a mix of resin binder and natural or pigmented quartz granulates. HIM quartz floors are decorative, durable and wear-resistant and can be used in all areas, varying from household applications to applications in the food and heavy industry.

2 types of quartz floors

We distinguish 2 types of quartz floors: Trowel and multi-layer floors.

Don’t hesitate to ask us which type fits your needs best!

Request informationHIM quartz floors can withstand almost anything: heat, moisture, chemicals, impacts, scratches and heavy equipment load.

We know everything about epoxy floors: how it is applied, what the advantages and disadvantages are and what it looks like once it has dried.

HIM floors are almost always available within 48 hours. In case of emergency, even the same day is possible.

Not entirely sure whether this floor is ideal for your situation? Quartz floors are mainly used in situations where the following features are highly valuated:

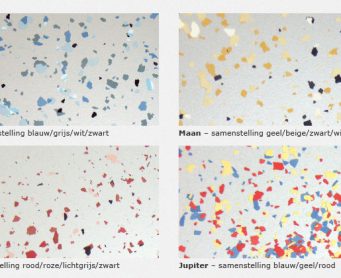

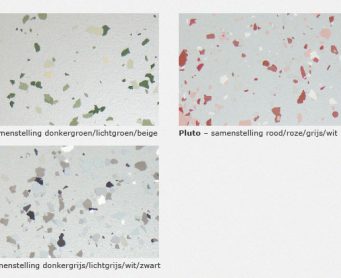

It is not a surprise that the appearance of a room is greatly influenced by the color of the floor. A dark floor gives a more robust and cozy impression and a lighter floor gives a more professional appearance, but can sometimes feel cold and clinical. We are happy to advise you and, thanks to more than 80 years of experience, we know everything about the effect of a floor on the intended space.