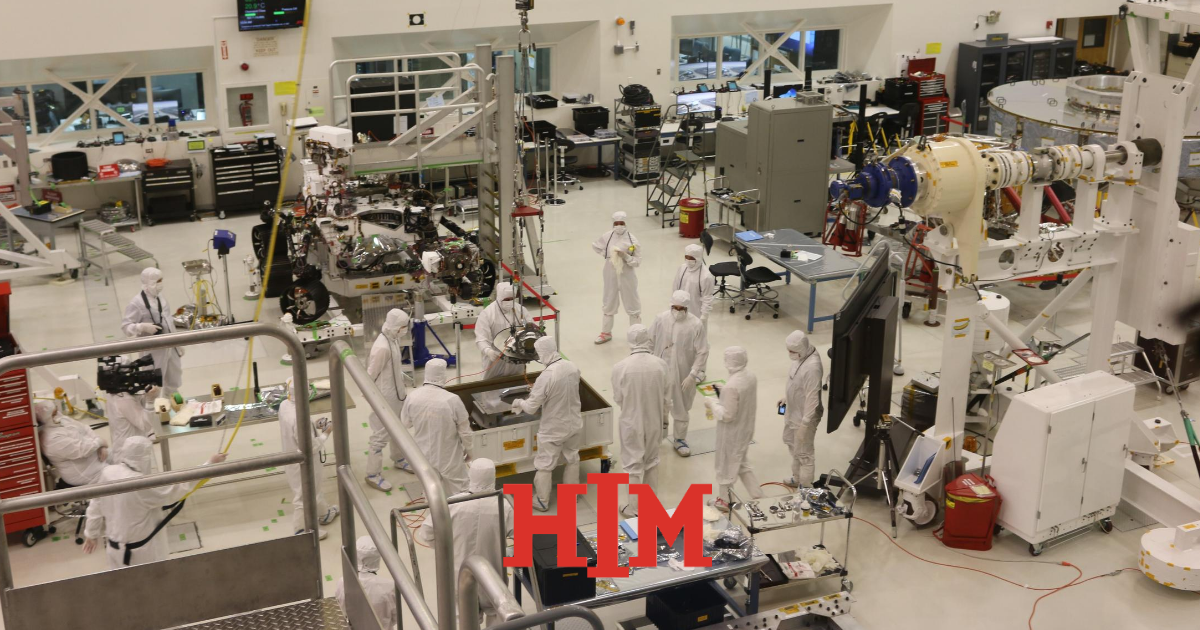

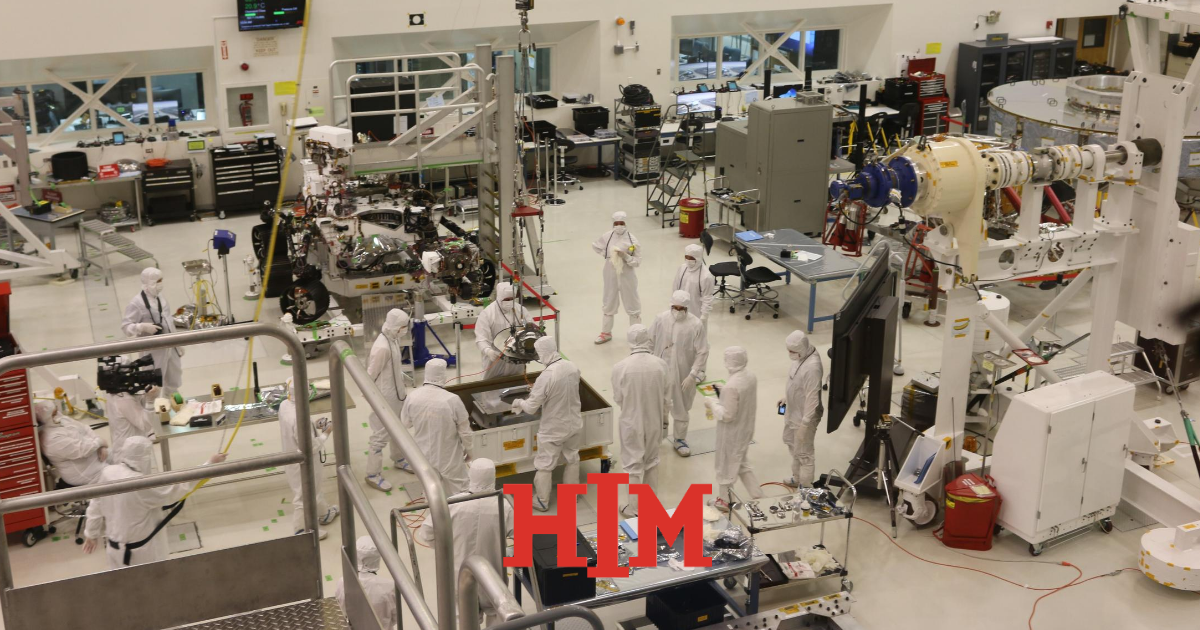

In cleanrooms, the build-up of electrostatic charge has a disruptive effect on safety. ESD coatings are equipped’s prevent dirt and dust buildup and minimize microbiological and electrical safety risks; high value properties on a cleanroom floor.

ESD coating as a system solution

ESD coatings prevent static discharge from being transmitted through the floor to man or objects in the working environment. The best antistatic effect is obtained when the cleanroom floor is built up as a three-layer system (or four, if the system is preceded by a primer or scraping). Such a system has the following structure:

- A conductive undercoat, which acts as a lightning conductor and electrostatic charge created by friction with the floor immediately discharges.

- A two components cast floor based on specially selected epoxy resins, hardeners, pigments, carbon fibers and inert fillers.

- A topcoat for minimizing personal loading.

ESD coating prevents contamination, damage and discomfort

A cleanroom floor must be kept sterile at all times to avoid microbiological hazards. So there is every effort to prevent the accumulation of dust and dirt. In addition, good cleanability is a hard requirement. The following operating benefits make ESD coatings indispensable on a cleanroom floor:

- ESD coatings prevent electrostatic charge build-up. Because of this characteristic, the floor does not attract dirt and dust. For example, the number of cleaning operations required to keep the floor sterile is greatly reduced. This greatly facilitates compliance with cleanroom hygiene regulations;

- High-tech equipment optimally protected. ESD-sensitive high-tech equipment is available in many cleanrooms. A low voltage can seriously decontrol the operation of the systems, causing impurities (often unnoticed) to creep into research results and/or batches produced. The conductive properties of the ESD coatings compensate for the voltage and direct the electricity to the earth;

- Avoid personal loading. Although personal loading has no interfering effect on the equipment used and compliance with hygiene requirements, it is most unpleasant for anyone exposed to it. In practice, people experience a person’s charge as an electric shock or a spark. A special anti-static topcoat prevents walking movements and other human actions from generating electrostatic charge.

Want to know more?

HIM ESD coatings meet the highest usage criteria and include allproperties to manage cleanroom operations. Would you like additional information about our ESD floors? Our product specialists are happy to help you. For additional information, please call +31 (0)251-276300 or send us a message via the contact page.

Download brochure

Publicatiedatum: 2021-09-28

Categorie: News